High-Quality Single and Twin Cylinder Diesel Engines Manufacturer

Reliable Portable and Stationary Diesel Generators Manufacturer

RELIABILITY AND POWER

THATTRAVEL WITH YOU

FEATURED PRODUCTS

THE CAMPES PROMISE

At Campes, we prioritize excellence by crafting high-performance engines with top-quality materials sourced from leading industry suppliers through strategic partnerships. Our critical components—like crankshafts, camshafts, and cylinders—are made from premium metals and alloys, ensuring strength, durability, and precision. We enhance longevity with rigorous testing using advanced tools like Brinell and Rockwell Hardness Testers, metallographic microscopes, and leak testing equipment for fuel tanks. Our meticulous process includes self-inspection, mutual inspection, and thorough final testing by skilled technicians, guaranteeing flawless, reliable products that meet the highest industry standards. Trust Campes for superior engines built for performance and durability.

Premium Materials for Engine

At our company, we prioritize excellence by selecting only the finest materials for our engine’s critical parts, including the crankshaft, camshaft, balance shaft, connecting rod, cylinder, cylinder head, cylinder head cover, and cylinder side cover. We source top-quality metals and alloys to ensure exceptional strength, durability, and performance. This meticulous material selection reflects our commitment to building reliable, high-performance engines that meet the highest industry standards. Trust us to deliver superior products engineered for longevity and precision.

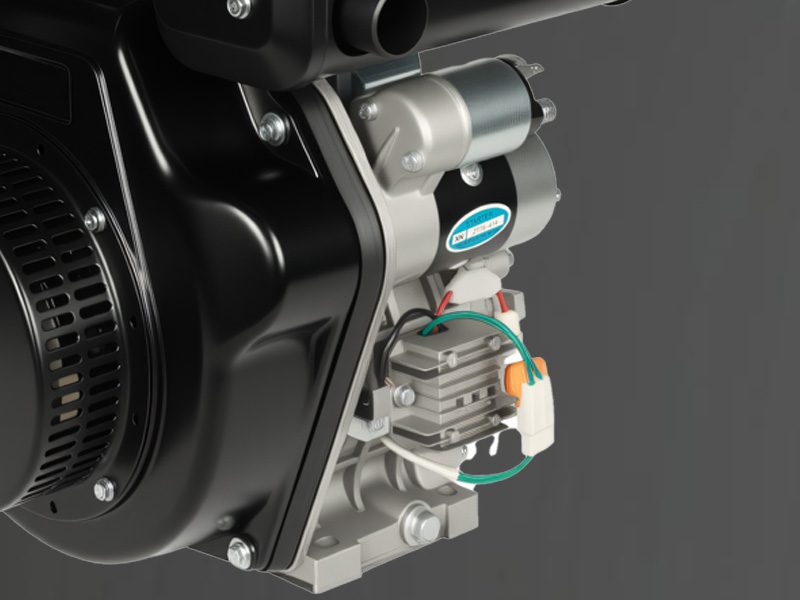

Best Components

At Campes, we ensure the highest quality for our engine critical components through long-term strategic partnerships with leading industry suppliers. These collaborations guarantee a stable, consistent supply of premium parts. By working closely with top-tier suppliers, we maintain exceptional material standards, ensuring strength, durability, and performance. This commitment to quality reflects our dedication to delivering reliable, high-performance engines that exceed customer expectations. Trust Campes for superior products built with the best components in the industry.

Detail Oriented

Campes is committed to precision in every detail. Prior to final assembly, we ultrasonically clean each critical component to eliminate surface dust, safeguarding the engine's longevity. In contrast, many low-end, budget machines often skip or inadequately perform this cleaning step. While this might not immediately impact machine function, it significantly compromises long-term durability.

Precision Adhesive Bonding

We enhance engine durability by applying high-performance adhesives to critical connection surfaces, ensuring strong, leak-proof joints. Our skilled technicians use advanced equipment for precise application, boosting structural integrity and longevity. This meticulous process reflects our commitment to quality, delivering reliable, high-performance engines for any application.

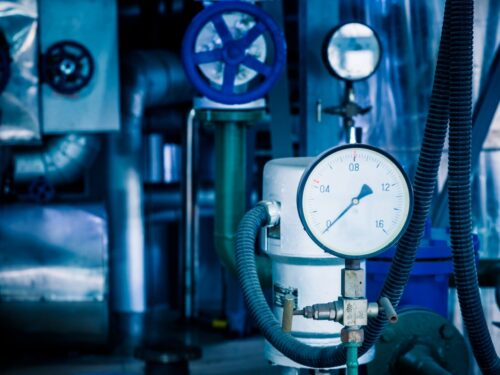

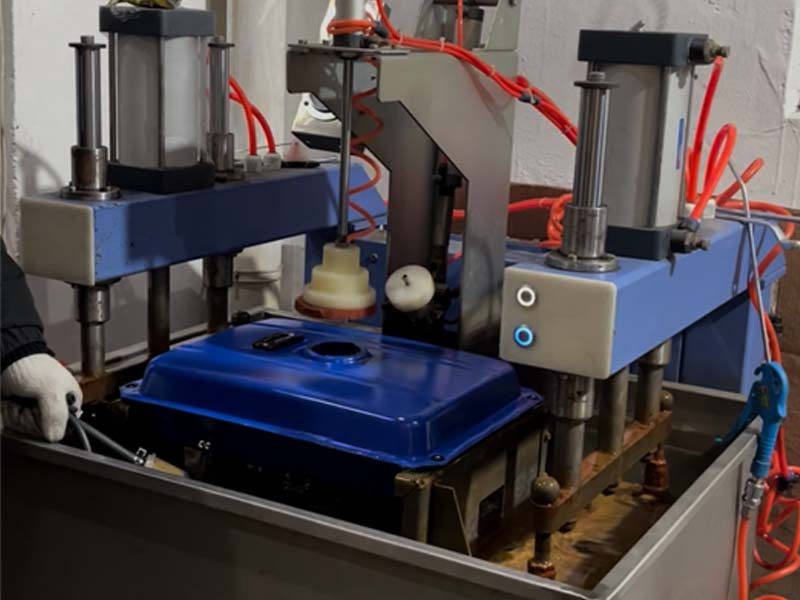

Incoming Quality Control

Check the air tightness of the fuel tank

At our state-of-the-art manufacturing facility, we ensure the highest quality and safety of fuel tanks through our cutting-edge leak testing equipment. This specialized system is designed to rigorously test the airtightness of fuel tanks, guaranteeing they meet stringent industry standards for performance and reliability.

Self-Inspection and Mutual Inspection

We ensure top-quality products through rigorous self-inspection and mutual inspection on our production line. Technicians meticulously check their own work and review colleagues’ efforts, minimizing defects and ensuring precision. This dual process reflects our commitment to excellence, delivering reliable, high-performance goods you can trust.

Rigorous Final Inspection

Every product undergoes a thorough final test before packaging to ensure flawless performance and quality. Our technicians use advanced methods to verify durability and specifications, eliminating defects. This commitment guarantees reliable, high-performance solutions you can trust.

Rigorous Final Inspection

Every product undergoes a thorough final test before packaging to ensure flawless performance and quality. Our technicians use advanced methods to verify durability and specifications, eliminating defects. This commitment guarantees reliable, high-performance solutions you can trust.

OUR BLOG

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.